Considerations when making up a slurry

Gavin Dooley PhD - Group Technical Director

Introduction This article outlines the considerations and factors effecting slurry make up and management. There are many factors to consider...

Stucco Application Methods – The Practice

Gavin Dooley PhD - Group Technical Director

In the article below, we will take what we learned in the first article to assess how the different stucco...

Fundamental Analysis into the Drying of Ceramic Shells – Part 2

Gavin Dooley & Matthew Everden, REMET

Introduction This article follows on from the original article by Manuel Guerra & Gavin Dooley as presented in the June...

Stucco Application Methods – The Theory

Gavin Dooley PhD - Group Technical Director

In the article below, I would like to discuss what the differences are within the two stuccoing methods within investment...

Factors Affecting Slurry Rheology

Manuel Guerra - Laboratory Manager & Gavin Dooley PhD - Group Technical Director

Purpose of Slurry Rheology Control Today, Foundrymen are interested in controlling casting quality. This includes the control of surface finish,...

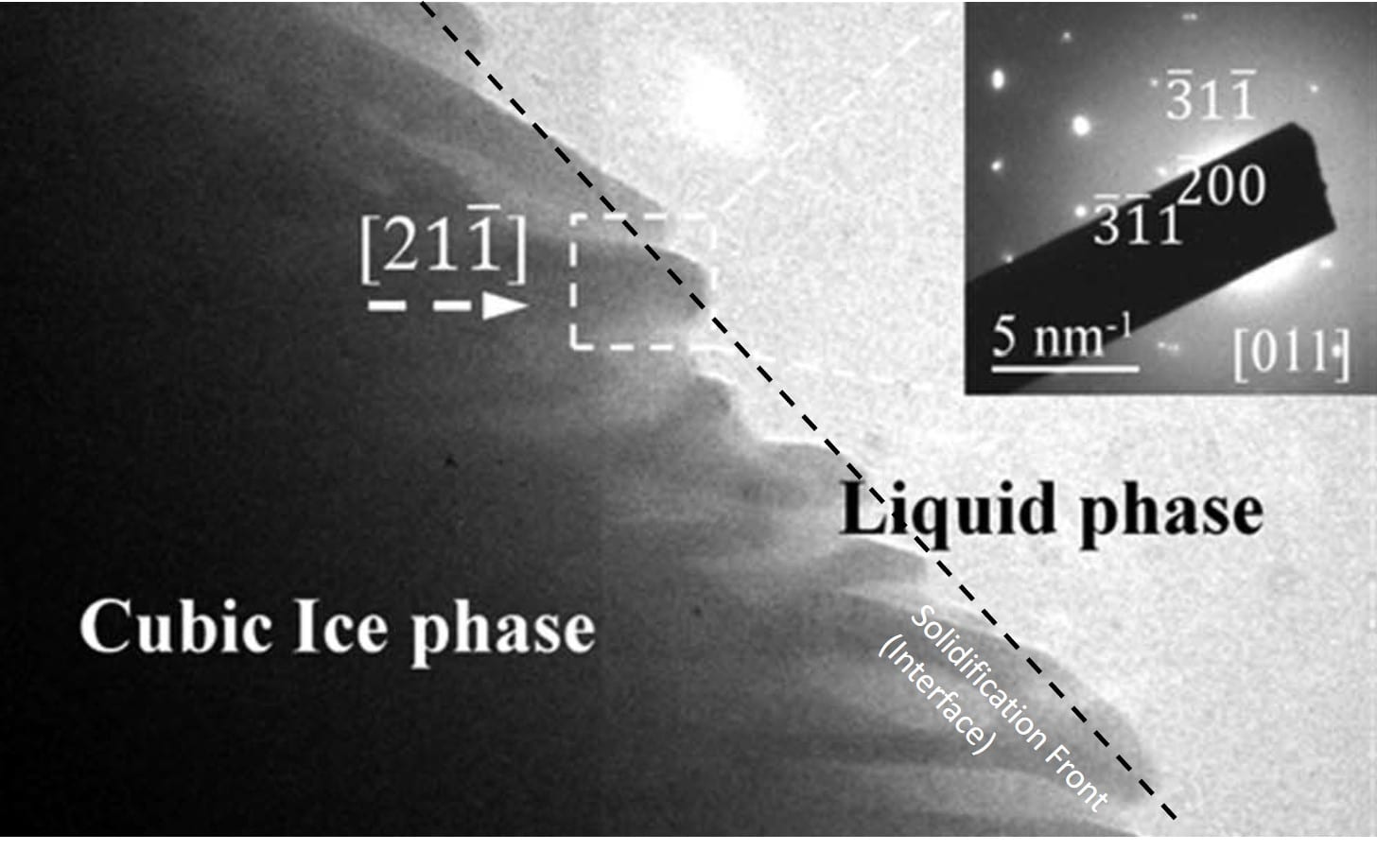

Effects of Freezing Conditions on Colloidal Silica

Kevin Lee PhD - R&D and Technical Process Engineer

What happens when the binder is kept in an environment of temperature < 0℃? When a colloidal silica binder is...

Drying of Ceramic Shells – The Practice

Manuel Guerra - Laboratory Manager

Introduction Following on from the first article on drying technology, this article outlines experimental work carried out within our lab...

Drying of Ceramic Shells – The Theory

Manuel Guerra - Laboratory Manager

It has been a while since we posted an insights article, I would like to present work carried out by...

How much does my shell cost?

Gavin Dooley PhD - Group Technical Director

In this short article I will show you how to calculate the true cost of a shell during production. By...

An analysis into Surface Tension – The missing link to a good prime coat?

Dr. Gavin Dooley PhD - Group Technical Director

I hope the title caught your attention! Below is a summary of the findings presented for the EICF European Casting...

Wax on Wax off – Part 1 – De-waxing the shell

Kevin Lee (Remet), Gavin Dooley (Remet), Howard Pickard (LBBC)

The de-waxing process is one of the most important steps in the Investment casting process. Kevin Lee has completed immense...

AdBond® QuikSet™ – A technical comment

Dr. Gavin Dooley PhD - Group Technical Director

Introduction Due to the success of my earlier article discussing the benefits of the FastForm™ wax product line, I thought...

Factors affecting shell strength and slurry life – a dive into the chemistry and microstructural effect

Kevin Lee PhD - R&D and Technical Process Engineer

Welcome to my first insight article on ceramic shell moulds. I am aware that there are already thousands of papers...

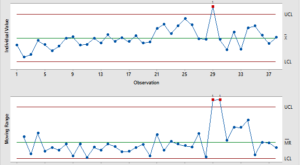

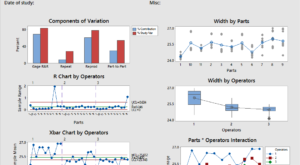

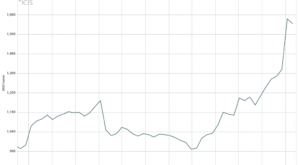

Use of Statistics in Consumable manufacture and control – Part two – Is it in control?

Dr. Gavin Dooley PhD - Group Technical Director

I hope I have not lost everybody since my first article! In my first article, (Use of Statistics in Consumable...

Use of Statistics in Consumable manufacture and control – Part one – Am I testing this right?

Dr. Gavin Dooley PhD - Group Technical Director

Introduction I hope I have not lost everybody by the heading of this article! In the following article series, I...

Slurry Testing; Common Pitfalls and Mistakes

Alex Spence - Senior Quality Controller

Welcome to my first insight article. I am Alex Spence, my undergraduate degree was in combined sciences, and I am currently...

Refractory Insight – Part 2: Testing

Alex Spence - Senior Quality Controller

Welcome to my second insight article for Remet UK. If you didn’t catch my first insight, on “Slurry Testing, Common pitfalls...

Refractory Insight – Part 1: An Introduction

Dr. Gavin Dooley PhD - Group Technical Director

Introduction Following a recent visit to an art foundry, I was prompted to write this article in relation to what...

FF>>Form® – A technical comment

Gavin Dooley - Group Technical Director

Cross Linked PolyStyrene – On the up and up! For any producers of investment cast parts, they are probably using...

Investment Casting Permeability

Gavin Dooley - Director of Technical Operations

Introduction My first three articles (Strength Part 1 | Part 2 | Part 3) dealt with the strength of materials,...

An Overview of Creep in Ceramics and Simple Strategies to Reduce its Significance in Equiaxed Investment Casting Moulds.

Bob Brown - Director of Sales and Marketing

A summary of creep models and prospective solutions to reduce its impact on the manufacture of equiaxed turbine blades in...

Integrated Management Systems: Badge or Bonus?

Bob Brown - Director of Sales and Marketing

REMET® UK runs a well-constructed Integrated Management System (IMS), into which it incorporates its certification under ISO9001, ISO 14001, OHSAS18001, and...

Investment Casting Hygiene: Its a Bugs Life!: Part 2

Bob Brown - Director of Sales and Marketing

Termination Day This post is the much awaited follow up to my post a few months ago with respect to the...

Investment Casting Hygiene: Its a Bugs Life! Part 1

Bob Brown - Director of Sales and Marketing

Enhanced colloidal silica binders, such as REMASOL, are composed of sub microscopic particles of silica suspended in latex and water...

pH Control in Investment Casting Slurries

Bob Brown - Director of Sales and Marketing

Thanks for the continued interest in these short posts: In this post we’ll talk about the measurement and control of...

Antifoam selection and use

Bob Brown - Director of Sales and Marketing

Previously I wrote about the use of surfactants and wetting agents in Colloidal silica slurries. Again many thanks for the...

Surfactants in Colloidal Silica Slurries

Bob Brown - Director of Sales and Marketing

I may have started a ball rolling! First of all thanks for the positive (and negative) comments on the previous...

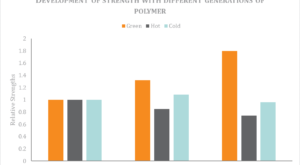

Investment Casting Strength – Part 3: Shell materials

Gavin Dooley - Director of Technical Operations

If you are still reading this series, then you have come through a journey of discovery of strength and how...

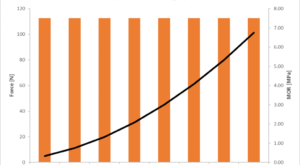

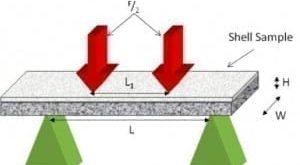

Investment Casting Strength – Part 2: The parameters

Gavin Dooley - Director of Technical Operations

In section one we discussed what happens when a sample is subjected to loading under flexural testing and the associated...

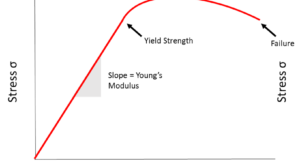

Investment Casting Strength – Part 1: The basics

Gavin Dooley - Director of Technical Operations

Hello everyone, as part of my new and exciting role within Remet®, I thought I would take some time to...

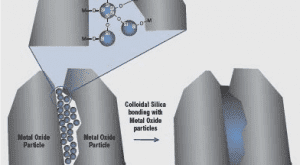

Using fine fused silica flours in primary slurries

Bob Brown - Director of Sales and Marketing

Prompted by material shortages and unmanageable price increases a few years ago, there has been a move away from fully...