Fast Form – A Case Study

Introduction

Remet has patented an innovative and novel un-filled wax which can perform dimensionally the same as filled wax with fantastic benefits:

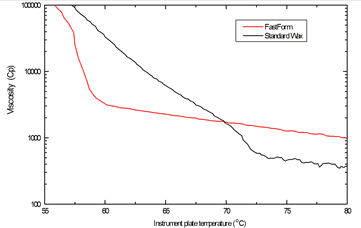

- Lower viscosity than traditional filled waxes to give superior filling in tight cavities, around cores and trailing edges

- Superior de-wax due to the viscosity drop at lower temperatures and lack of filler

- Over 50% reduction in processing time

- Cleaner burnout

- Adaptable shrinkages based off current tool dimensions and waxes

- Increased recyclability

Typically 50% Reduction in Processing Time

Numerous customer trials have shown due to the amazing properties of FF>>Form waxes, cycle time can be reduced without compromising sink, shrink and deformation on complex wax parts.

Unfilled Pattern Wax Technology

Remet has developed FF>>Form wax utilising the innovative crystalline properties of waxes to product a wax with these amazing properties. No exotic raw materials are utilised to gain these properties. It is all in the chemistry!

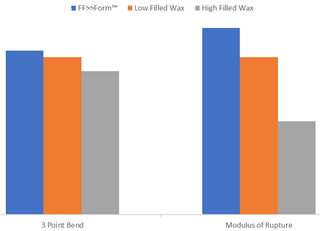

Dimensional Control

FF>>Form wax is unique in that a change in formulation carried out by our technical department can shift dimensions to the required specifications without changing other key properties of your wax. We can develop a bespoke wax with little effort that will dimensionally fit specifications required.

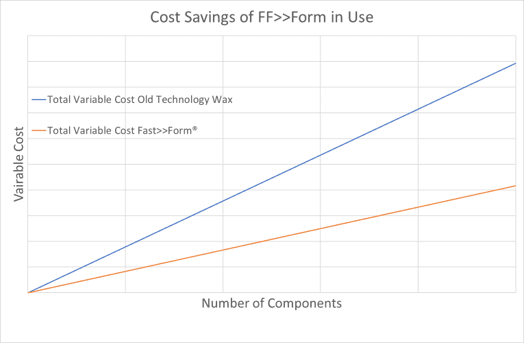

Financial Benefits

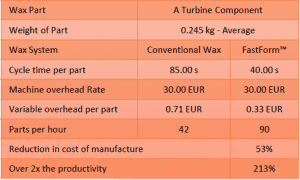

Of course every foundry is different therefore the table below is an example of the savings possible using FF>>Form Wax.

FF>>Form® – A Case Study

Advantages

REMET has developed a new technically advanced, and patented, unfilled pattern wax. FastForm has been proven to offer great technical advantages to the end user.

In particular, REMET FastForm pattern wax:

- Drastically reduces cycle time

- Reduces associated energy costs and wastage

- Fully customisable shrinkage

- Reduced sink

- Has increased dimensional capability

- Autoclaves freely with little residue

- Produces reduced residual stress, and therefore reduced warp after injection

- Reduces noxious emissions on firing

FF>>Form Trial Data

In a recent trial, and aerospace guide vane was injected using FastForm, alongside a competitors wax:

A summary of the results follow:

As can be clearly seen productivity, and hence inversely, cost, is leveraged to a high degree when FastForm is used. For example, a 30% reduction in cycle time will net a 42% increase in productivity and a 42% reduction in overhead consumption.

Obviously there is virtually no difference in the cost of wax used, however, FastForm’s lower density assists in reducing cost per unit volume injected. Due to FastForm’s exceptional, and surprising speed of set up the variable cost, is dramatically reduced.

Given the data received during the trial, the following figure was created to display the Cost Saving achieved using FastForm over a manufacturing campaign.

REMET®: Unlocking tomorrow’s technology today…