Refractory Insight – Part 1: An Introduction

Introduction

Following a recent visit to an art foundry, I was prompted to write this article in relation to what makes a successful or unsuccessful refractory. There is a wide range of refractories available which contribute to the overall properties of the slurry and ceramic shell and knowing how these can alter your slurry is pivotal to your process being successful. In this article we will review the manufacturing processes which go into these materials, what is meant by fused, calcined and “refractoriness” and also some testing which can be conducted to analyse material properties of these refractories. So, let us begin…

The term refractory is a name given to materials which can retain strength at high temperatures. ASTM C71 describes them as:

“Non-metallic materials having those chemical and physical properties that make them applicable for structures, or as components of systems, that are exposed to environments above 1,000 F or 540C.”

As you can see every shell system is a refractory as it operates above the temperature outlined within the definition. Refractories can range from flame retardant systems, kiln linings, crucibles etc. However, within this article, I am going to just discuss what is useful for the shell room; flours and stuccoes. One thing to note here is that a full review of the health and safety datasheets should be conducted before using and processing these materials as each have their own risks and impacts.

Requirements of a refractory

There are many properties which are required for a refractory within a shell system. For flours some of these are given and discussed below:

- Inertness: It is key to ensure the refractory is both inert within the slurry, to ensure it does not gel the slurry, and during pour when metal interacts with the prime surface.

- Particle Shape: The flour particles must allow each other to flow over each other, helping with the coverage of the wax pattern during dipping. The minerology and grinding mechanism will affect the overall shape of the particles.

- Controlled Fines: Dust within a flour, causes issues with the permeability of the overall shell during casting. However on the other hand, this can also increase the strength of the shell system.

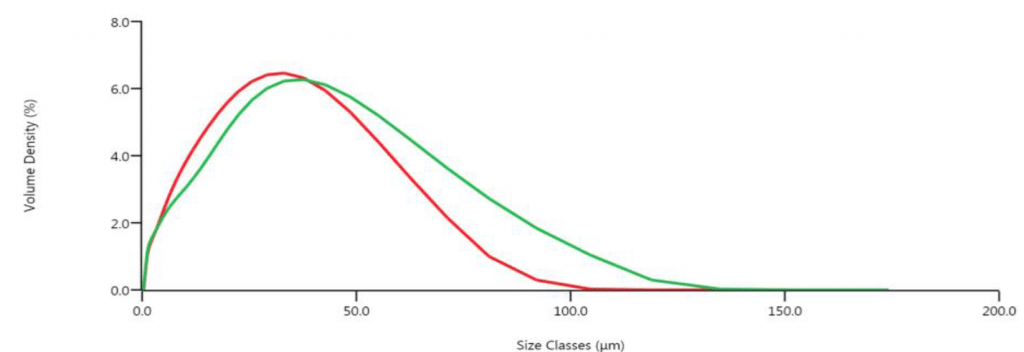

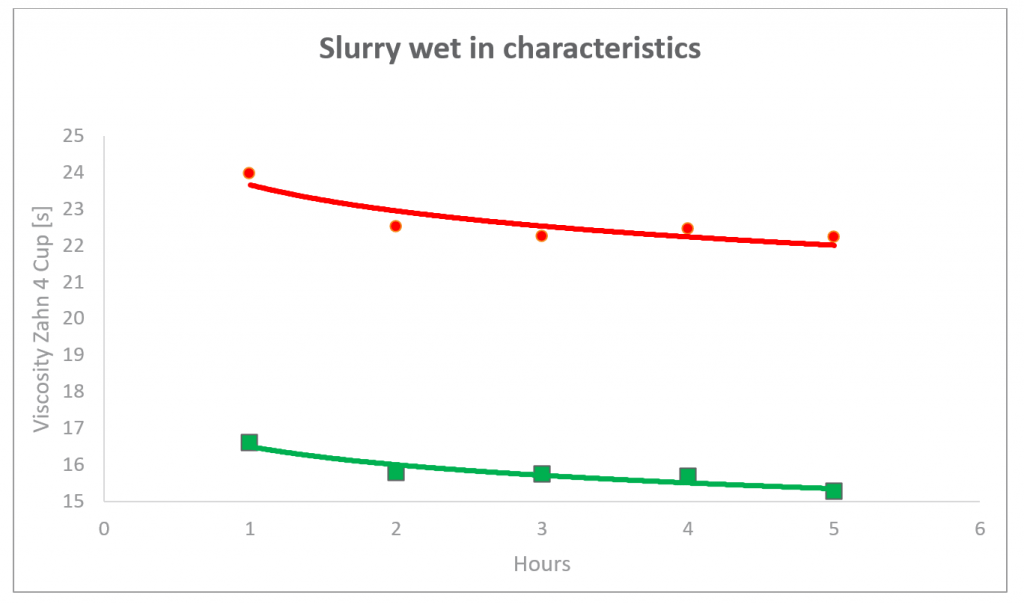

- Repeatable Particle Size Distribution (PSD): PSD is defined by the milling process within a given mine or processing site. Ensuring each batch arriving into a shell room has the same PSD as historical batches ensures the viscosity, strength and permeability will remain in control within the process. Only recently, was a material with slight difference in PSD compared side by side and found to cause a 5 second shift (Zahn #4) to a slurry due to the varying particle sizes. This can be seen below:

Figure 1: PSD of two flours

Figure 2: Slurry wet in characteristics

- Thermal conductivity: The thermal conductivity of a shell is characterised by the refractory used within it and is an important property of any shell system. How much heat is dissipated from the shell will affect the cooling characteristics and subsequent grain size of the metal.

For stuccoes, all the above properties apply but there are two more properties which must be considered:

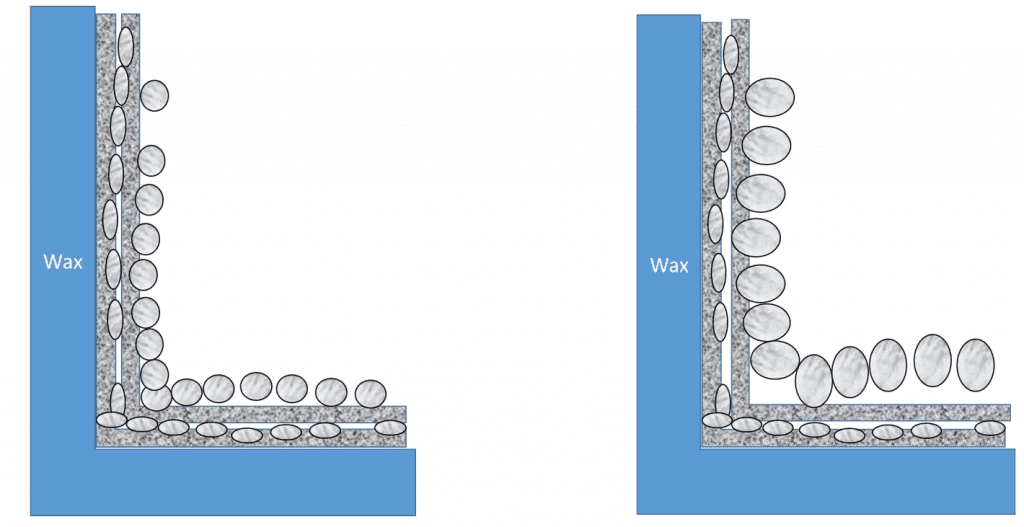

- Particle size: Again, the particle size is pivotal to ensure the mechanical properties of the shell is maintained. However, for stuccoes, it is also key to ensure the required definition is attained for the sample. If the particle size is too large, the surface finish or intricate details of a wax part is lost. To combat this, intermediate coats can be applied to ensure details from the wax pattern is not lost This can be seen clearer within Figure 3.

Figure 3: Stucco particle size can affect the definition of a part of different geometries

- Friability: Friability is a property which can affect how the material performs during production. Friability is the ability of a particle to reduce in size and break down during processing. The use of fluidised beds and particularly rainfall sanding can affect how the particle size changes over time in production and hence the amount of dust which is present within the process.

Within the next article, we will discuss some of the most commonly used refractories on the market and how they can be analysed and tested. Stay tuned!

< Back to insights